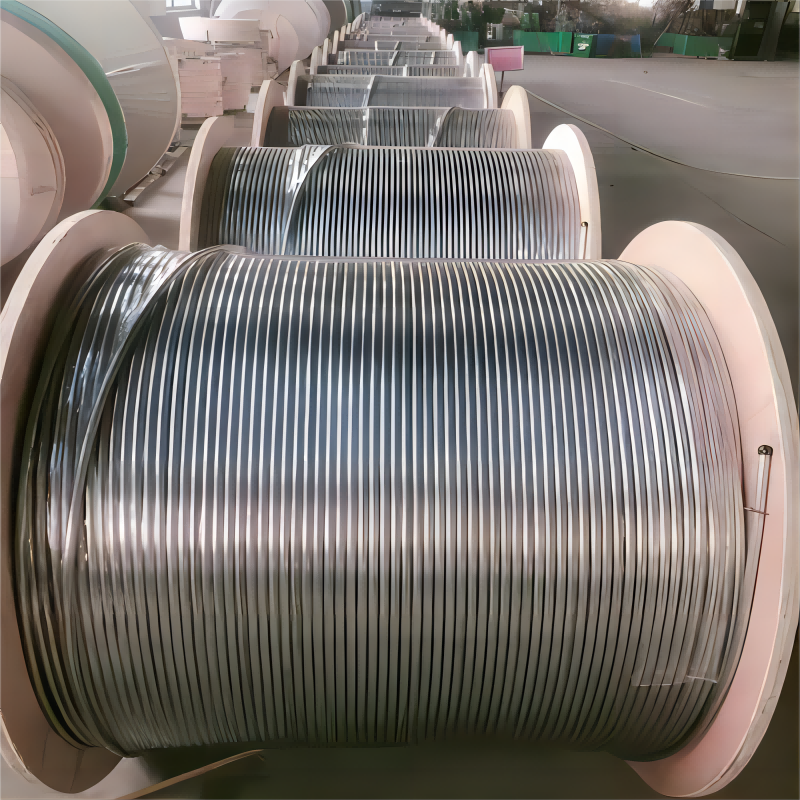

| Deskripsyon | Tib bobin asye pur | ||

| Materyèl & Estanda & Gwosè | Materyèl: 201,202,301,304,304L,310S,316,316L,321,347 Estanda: ASTM (ASME) SA / A312 / A213 / A269, DIN, JIS, EN | ||

| Soti Dyamèt: Φ6mm-25mmWall Epesè:Φ0.7mm-2.11mm Tolerans: OD: ± 0.08mm, WT: ± 10% | |||

| Longè | Dapre diferan gwosè, yon sèl longè bobin se nan 500 mèt tib la bobin antye pa soude pwen. | ||

| Tretman andigman | marinated oswa polonè rkwit | ||

| Teknik | Fwad woule premyèman, Lè sa a, frèt trase bobin | ||

| Kalite livrezon | Mou | ||

| Kalite | San pwoblèm ak Welde | ||

| Aplikasyon | Se tib bobin asye pur lajman ki itilize nan perçage lwil oliv, pwodui chimik, endistri fabrikasyon vapè, echanj chalè ak endistri chimik kondansasyon refwadisman, tiyo gaz elatriye. | ||

Klas asye pur

| Konpozisyon chimik | Konpozisyon materyèl | 201 | 304L | 304 | 316 | 316L |

| C | ≤0.15 | ≤0.03 | ≤0.08 | ≤0.08 | ≤0.03 | |

| Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

| Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤2.00 | |

| P | ≤0.06 | ≤0.035 | ≤0.035 | ≤0.035 | ≤0.035 | |

| S | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | |

| Cr | 16-18 | 18-20 | 18-20 | 16-18 | 16-18 | |

| Ni | 3.5-5.5 | 8-12 | 8-10.5 | 10-14 | 10-14 | |

| Mo | 2.0-3.0 | 2.0-3.0 | ||||

| Pwopriyete mekanik | Atik materyèl | 201 | 304L | 304 | 316 | |

| Fòs rupture | ≥535 | ≥520 | ≥520 | ≥520 | ||

| Sede fòs | ≥245 | ≥205 | ≥205 | ≥205 | ||

| Ekstansyon | ≥30% | ≥40% | ≥35% | ≥35% | ||

| Dite (HV) | <253 | <200 | <200 | <200 | ||

Tan poste: Jan-20-2023